Tri-R Technologies

TR-4

BUILDER'S

MANUAL

This Builder's Manual is NOT the official manual

as published by TRI-R Technologies.

FUSELAGE

Quick Links to Wing Assembly Sub-Sections:

SPAR

PREPARATION

LEVELING

AND FIXTURING

SPREADER

STICKS

TEMPORARY

FITTING OF THE FUSELAGE TOP

FIREWALL

FIREWALL

FRONT FACE

ADDED REINFORCING IN FIREWALL AREA

STATION

139.5 BULK HEAD

STATION

180.5 BULKHEAD

MAIN

SPAR AND OUTBOARD SPAR PRE ASSEMBLY

REAR

SPAR

MAIN SPAR LOCATION AND INSTALLATION

POSITIONING

SPAR

MOUNTING LAMINATIONS

MAIN

GEAR BOX REINFORCEMENT

SEAT

FRONT BULKHEAD & CONTROL MOUNT

FUSELAGE

BELTLINE

CONDUITS

FRONT SEAT BACK ASSEMBLY

REAR

SEAT BACK INSTALLATION

CONTROL

CONSOLE - FRONT SEAT AREA

ELEVATOR

IDLER BELL

CRANK

SEAT BOTTOM ASSEMBLY

FRONT

SEAT

REAR

SEATS

FRONT

FLOOR ASSEMBLY

STICK

LINKAGE ASSEMBLY

FLAP

HANDLE ASSEMBLY BRACKET

AILERON

IDLER INSTALLATION

FLAP ACTUATION TORQUE TUBE INSTALLATION

RUDDER

IDLER LEVER INSTALLATION

HORIZONTAL

STABILIZER

INSTALL

RUDDER POST

ELEVATOR AND PUSH/PULL ROD

INSTALLATION

RUDDER CABLE ROUTING AND

INSTALLATION

MAIN

GEAR INSTALLATION

BRAKE

LINE INSTALLATION

FIN

RIGHT HALF INSTALLATION

INSTALL

LEFT FIN HALF

HANGING

RUDDER

INSTALLATION

OF FUSELAGE TOP

BAGGAGE

AREA BACK PANEL

DOOR

PREPARATION

WINDOW

INSTALLATION

DOOR

LATCH ASSEMBLY

MOUNT

DOORS

LATCH

PLATE INSTALLATION

AIR

STRUT INSTALLATION

REAR

WINDOWS

INSTRUMENT

PANEL

WINDSHIELD

FIREWALL

-

The firewall will be fabricated from the 1/4 inch plywood piece included

in the kit parts. This piece of plywood should have the outline and location

of major features (such as engine mounting locations) marked on it by the

factory. Some slight amount of trimming will be required from the factory

line to the final fit, to the fuselage.

-

Some of the plywood may be warped from shipping so some degree of straightening

should be performed at this time. Storing on a flat level spot with weights

or clamping with some one by four material should flatten the material. In

severe cases temporarily attach some I by 4 strips on edge to the engine

side of the plywood to hold it flat.

-

The firewall cutout should be inserted into the forward portion of the two

fuselage halves and pushed back to the reference location. The back surface

of this plywood firewall is to be set at station 0.0, with considerable care

and precision, since this will be used as the reference for many of the assembly

procedures. Station 0.0 is described as the edge of the "joggle" for the

cowling rear overlap (see figure 4-4).

Figure-4: Firewall Position

|

-

Four holes about 1/16 in. dia. may be drilled around the perimeter, through

the edge of this "joggle" to visually determine the correct location.

The plywood may be temporarily spaced with large pins or small nails through

these holes and may be temporarily secured with small nails or pins through

small holes drilled to the center of the plywood.

-

Assure that the firewall is vertical and square in place. Use the level line

on the firewall to assure proper vertical placement relative to the Waterline

references on the lower fuselage section (the joggle at WL -1.25 and the

trimmed edge at WL 0.0).

-

Verify the fit with the upper fuselage half before ''attaching'' the firewall

panel to the lower section with five minute epoxy ( or CA ). As mentioned

before, when "tacking" in place with five minute epoxy (or CA), be careful

not to spread the epoxy over a wide area. The fast curing epoxies have

significantly lower structural bond strength than that of the slow cure mixes,

and any area covered by the fast epoxy will have this "weak link" in the

joint. Keep the five minute epoxy "tacks" as small and local as practical,

.

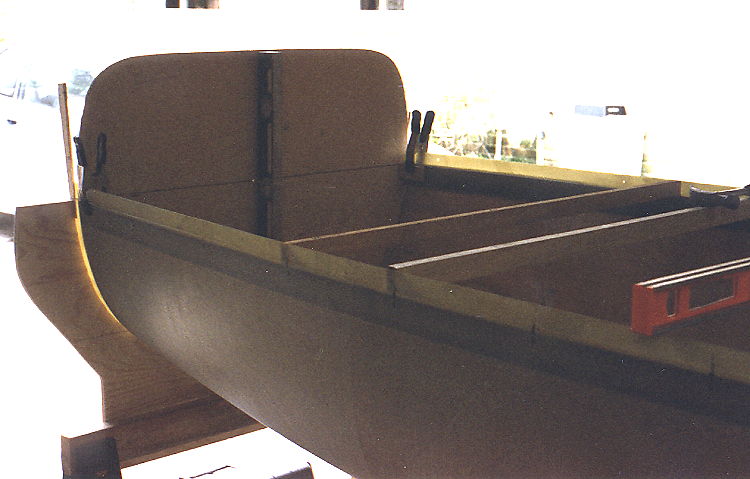

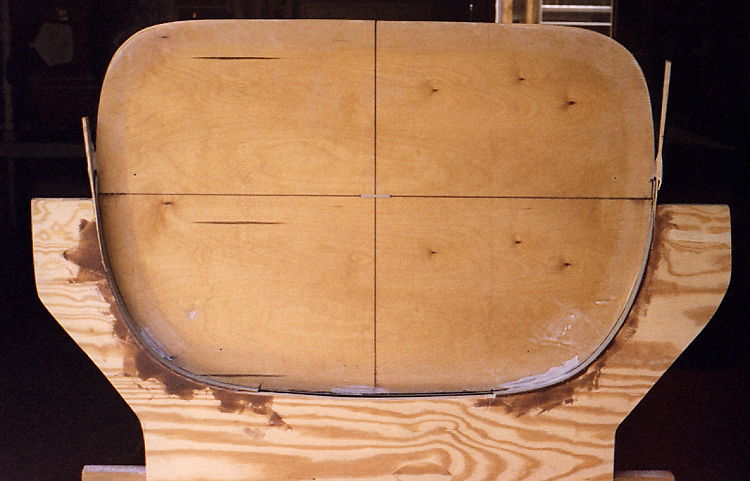

Figure 128-130: Filewall Positioning

|

|

|

Measuring from the tail to square the firewall to the fuselage.

Extending

the measurement point increases the accuracy of the measurement. |

A level attached to the inside of the firewall helped in the

level process and

to remove a bow from the plywood. |

Horizontal line is at the waterline 0.0

and the vertical line is center line. The shims helped clamp sides

against

firewall during bonding. |

FIREWALL FRONT

FACE

-

Prepare the inner surface of the fuselage flange area and several inches

back from the zero station in preparation for the bonding operation. As always,

remove all peel ply and debris and clean and roughen these areas.

-

Also prepare the forward and aft face of the firewall for bonding. Roughen

the bonding areas with very course sand paper (50 or 80 grit)

-

Trim off the forward facing cowl flange of the bottom of the fuselage between

BL-8L and BL- 8R (a total of 16 inches wide) and radius the edge.

-

Prepare any of the remaining inner surface of the flanges and the local bottom

surface of the fuselage for bonding.

-

MICRO/FLOX fillet the joint in all areas. Make up enough 3 inch wide two

ply pre-lam BID tape to apply to the flange/firewall joint on each side around

the firewall to the fuselage bottom surface.

-

The engine mounting points will be marked on the plywood firewall panel.

It will be beneficial to drill small pilot holes through the firewall to

denote the location of the engine mount bolts.

-

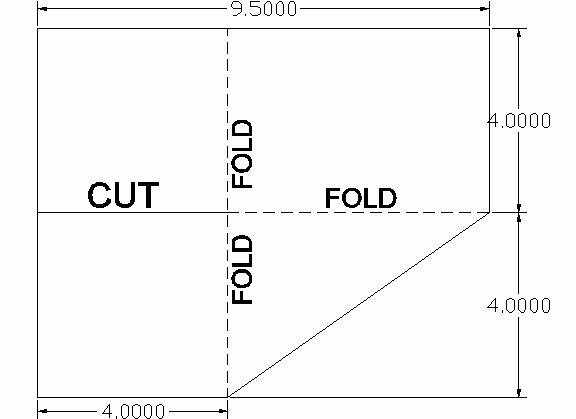

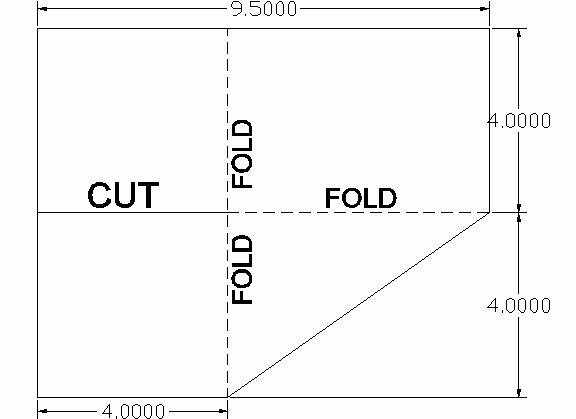

Cut out the triangular shaped gussets and the firewall cross stiffening strip

from the same plywood panel that was used for the firewall. The patterns

for these parts should also be factory marked on this panel.

The full width stiffener should be tied into the edges of the upper gussets

(cut to length if necessary).

-

Attach these plywood gussets and the firewall cross stiffening strip on the

inner surface of the firewall panel and to the lower fuselage section inner

wall with dabs of five minute epoxy (CA). The location for these stiffeners

is shown in figure XXX.

Figure -5, Fire wall gussets and stiffener.

|

-

The lower edge of these upper triangular gussets shall be aligned with the

top surface of the upper edge of the fuselage flange (waterline 0.0). These

gussets should be angled upward such that the lower surface of the plywood

is 1.5 inches from the center of the engine mount bolt hole. This will provide

adequate clearance for the washer which will be installed at each of these

mounting points. Ref. Figure 4-5

-

Firewall has been initially bonded into

place and bracing tacked in place.

|

Note horz and vert alignment lines. The

two holes are for a nylon strap to hold a tape

measure for one handed measurements. |

-

A fillet of dry FLOX should be worked into place on the underside of the

joint along the fuselage flange providing proper backing for the subsequent

layers of BID.

-

The lower gussets of this upper set will be mounted with a 1.5 inch clearance

to the mounting bolt holes and horizontally. Ref. figure 4-5

-

The gussets for the lower mounting holes shall be installed 1.5 inches on

the inboard side of the engine mount bolt center line location as marked

on the firewall pattern and shown in the figure 4-5.

-

Note all the areas that will be covered by the bonding layers of BID. Clean

and abrade these areas with coarse sandpaper and then wipe down with MEK

or Acetone .

-

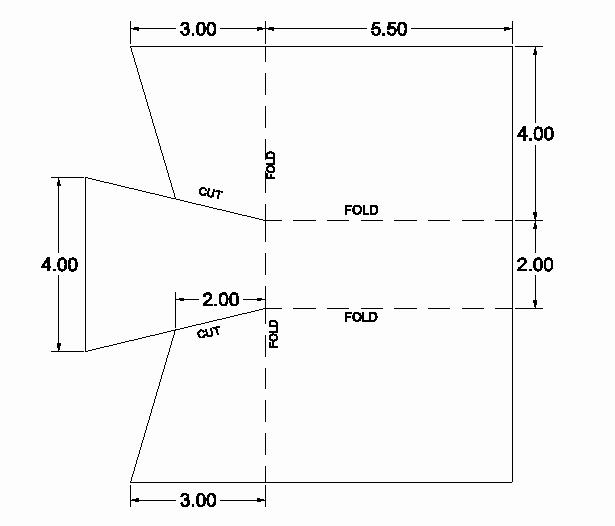

Make paper patterns in roughly the shape and sizes shown in figure 4-6, 4-7

& 4-8.

Figure -6, Gusset pre lams.

|

Figure-7: Gusset pre lams.

|

Figure-8: Between lower gusset pre lam.

|

The areas between the upper braces will be the most demanding because of

the a angle between the gussets. Try to optimize the pattern to provide full

coverage of the firewall in the bolt area with the three layers of each overlap

( 24 layers total in these mounting bolt areas).

-

Make up two 4 layer BID sections of the required size before hand. NOTE:

make the first 4 layer section oversized in order to provide generous added

overlap on the firewall surfaces. Make up these reinforcements in two stages

with decreasing amounts of overlap of about 1 inch in each stage. This will

avoid dumping all the concentrated loads on one line. We recommend that you

use the suggested procedure for "pre-lams" in the following instructions.

The lower engine mount areas have only one plywood angle per hole. The area

between these gussets with a total of 8 plies of pre-lam. This is the large

pattern - 18 inches long. (this is the nose gear mounting area). The fire

wall area next to the gusset will have the corner overlapped for a total

of 16 plies.

The other side (bolt hole side) will also get an 8 layer set of plies, doubling

the overlap at the mounting bolt points for a total of 16 plies at this time,

(4 added plies will be installed during floor installation).

Before each new lay-up wet out the surface that the pre-lam BID will cover

with a thin coat of brushed on epoxy. This applies to all areas where the

pre-wetted BID is to be applied. This helps to assure a good bond in these

areas.

-

Prepare the first 4 ply pre-lam for a upper gusset set and apply to the firewall.

Remove one layer of plastic and install between each set of gussets with

the wet side to the structure. Fold the "ears" of this BID such that there

is the required number of overlaps bonded on the back side of the firewall

where the holes will be subsequently drilled for the mounts. Remove the plastic

backing as you install the glass cloth to avoid having any plastic in the

overlap areas. Work any bubbles out of the resin with a brush or squeegee.

DO NOT MAKE UP MORE THAN ONE 4 PLY PRE-LAM AT A TIME AS YOU MAY EXCEED

THE WORKING TIME OF THE RESIN AND WILL HAVE TROUBLE REMOVING AIR BUBBLES

AND GETTING THE PRE-LAM TO LIE FLAT.

-

Prepare the second 4 ply pre-lam for the same upper gusset set and apply

over the first pre-lam. Follow the same procedure as above and in all subsequent

operations.

-

Insure that all air bubbles are remove and the pre-lam fit is good.

-

Do the same as above to the second upper gusset set.

-

Prepare the first 4 ply pre-lam for the underside of an upper gusset set

and apply to the firewall.

-

Prepare the second 4 ply pre-lam for the same underside and apply.

-

Do the same as above to the second upper gusset set.

-

Prepare the first 4 ply pre-lam for the lower firewall center section (between

the two lower gussets), and apply.

-

Prepare the second 4 ply pre-lam and apply to the first.

-

An added 6 by 10 inch 4 ply prelam should be bonded between the two bottom

engine mount gussets with a 3 inch overlap on each the firewall and the fuselage

bottom surface as added strength for the lower gear mount.

-

Again, insure that all air has been removed and the prelam lays flat against

all surfaces, especially where the firewall to fuse fillet is.

-

Following the procedures above, make up each set of 4 ply ( two sets of four,

each side of gusset, for a total of 8 ply’s ) pre-lams and apply to

the fuselage at the lower outside (engine mounting hole side) of the lower

gussets.

Completing the upper surface of the upper gussets ( which will be laminated

into the upper fuselage half ) will require special treatment and will be

delayed until the fuselage top is being permanently installed. ( Except as

noted below )

Any previously cured BID layers which will be bonded to in later steps must

be roughened and cleaned prior to applying added layers. This applies to

any portion of the assembly process, and should be kept in mind when scheduling

lay-up work . What you leave unfinished in one work session will have to

be re prepared before continuing at the next work session.

ADDED

REINFORCING IN FIREWALL AREA

-

Bond the uncovered upper surface of the cross stiffening strip in place with

a 6 layer BID tape. Use roughly a three inch overlap on the plywood firewall,

and a piece long enough for a full overlap on the upper engine mount gussets,

(trim this prelam at the fuselage edge - this section will be bonded to the

fuselage after the top is installed)

-

Do the same thing with a 3 layer BID tape on the lower surface of the crosswise

stiffener but just use a 2 inch overlap.

This is the reinforcement for the upper nose gear attach point. The heavy

loads on this gear mounting area are the reason for the generous number of

layers. Green trim the surplus glass cloth overhanging the edge of the plywood

parts or grind these edges to shape after curing.

IMPORTANT - Any remaining unbonded perimeter of the firewall and the lower

fuselage section, should be taped with a two layer three inch wide BID tape.

Reference figure XXX showing engine mount reinforcements.