Tri-R Technologies

TR-4

BUILDER'S

MANUAL

This Builder's Manual is NOT the official manual

as published by TRI-R Technologies.

FUSELAGE

Quick Links to Wing Assembly Sub-Sections:

SPAR

PREPARATION

LEVELING

AND FIXTURING

SPREADER

STICKS

TEMPORARY

FITTING OF THE FUSELAGE TOP

FIREWALL

FIREWALL

FRONT FACE

ADDED REINFORCING IN FIREWALL AREA

STATION

139.5 BULK HEAD

STATION

180.5 BULKHEAD

MAIN

SPAR AND OUTBOARD SPAR PRE ASSEMBLY

REAR

SPAR

MAIN SPAR LOCATION AND INSTALLATION

POSITIONING

SPAR

MOUNTING LAMINATIONS

MAIN

GEAR BOX REINFORCEMENT

SEAT

FRONT BULKHEAD & CONTROL MOUNT

FUSELAGE

BELTLINE

CONDUITS

FRONT SEAT BACK ASSEMBLY

REAR

SEAT BACK INSTALLATION

CONTROL

CONSOLE - FRONT SEAT AREA

ELEVATOR

IDLER BELL

CRANK

SEAT BOTTOM ASSEMBLY

FRONT

SEAT

REAR

SEATS

FRONT

FLOOR ASSEMBLY

STICK

LINKAGE ASSEMBLY

FLAP

HANDLE ASSEMBLY BRACKET

AILERON

IDLER INSTALLATION

FLAP ACTUATION TORQUE TUBE INSTALLATION

RUDDER

IDLER LEVER INSTALLATION

HORIZONTAL

STABILIZER

INSTALL

RUDDER POST

ELEVATOR AND PUSH/PULL ROD

INSTALLATION

RUDDER CABLE ROUTING AND

INSTALLATION

MAIN

GEAR INSTALLATION

BRAKE

LINE INSTALLATION

FIN

RIGHT HALF INSTALLATION

INSTALL

LEFT FIN HALF

HANGING

RUDDER

INSTALLATION

OF FUSELAGE TOP

BAGGAGE

AREA BACK PANEL

DOOR

PREPARATION

WINDOW

INSTALLATION

DOOR

LATCH ASSEMBLY

MOUNT

DOORS

LATCH

PLATE INSTALLATION

AIR

STRUT INSTALLATION

REAR

WINDOWS

INSTRUMENT

PANEL

WINDSHIELD

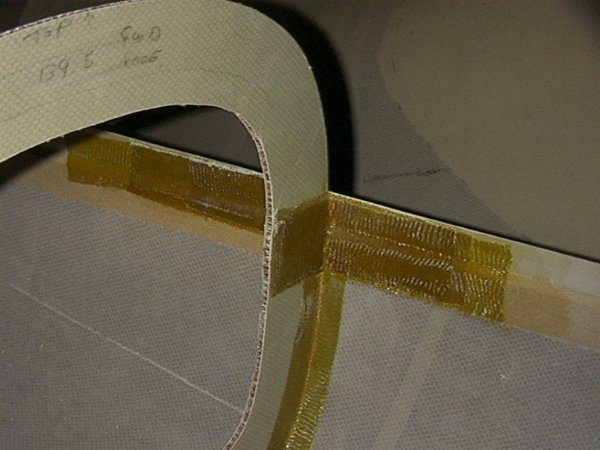

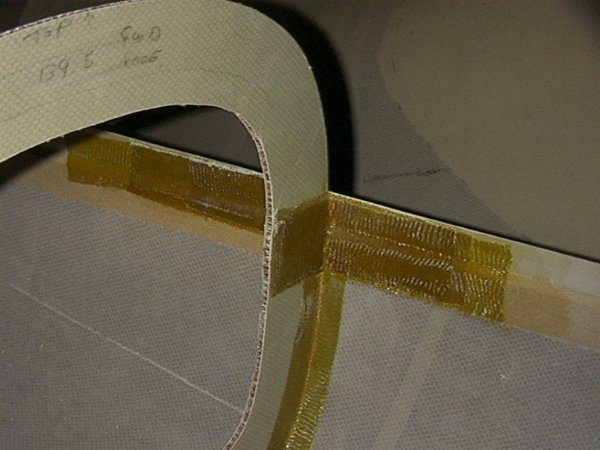

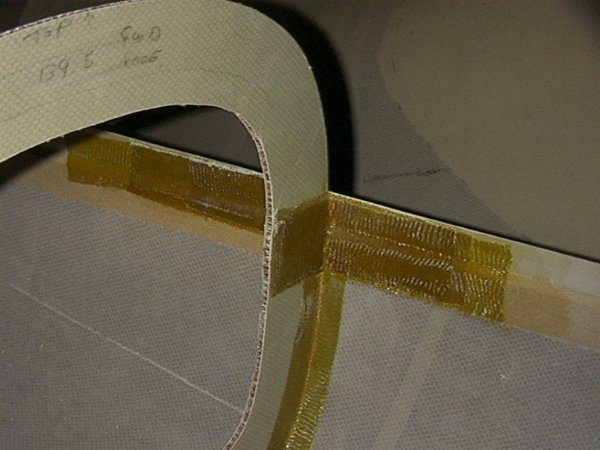

STATION 139.5 BULK

HEAD

The mid tail cone bulkhead is located at station 139.5. This bulkhead is

located at the joint between the fuselage top section and the right and left

hand fin halves. This bulk head is cut from a section of the two ply prepreg

panel that has the outline of this part drawn on the panel at the factory.

-

Cut this part out carefully since the station 180.5 bulkhead is outlined

in the center, and will be cut out from this part. Use a fine tooth saber

saw blade or similar tool for this operation. The outline provided is on

the generous side so some trimming or block sanding may be required to fit

it to the two fuselage halves.

-

Cut out the center section containing the 180.5 bulkhead and set it aside

for the next step. Carefully install and remove the fuselage top half for

fitting these components.

-

The 139.5 station location is to the front face of this bulkhead panel. Remember

that the station 0-0 reference is at the ""joggle"" where you lined up the

firewall, reference these locations from that point. Test fit the bulkhead

into the proper position, trimming as required for a good fitted joint, and

prepare both the bulkhead surface and the inner fuselage surface for bonding.

Mark the upper fuselage edge position (Water line 0.0) on the bulkhead.

-

Fit the bulkhead and align it carefully. Secure in place to the bottom fuselage

half with some dabs of five minute epoxy.

-

When it is secure enough to work with, bond it to the lower section with

two layers of two inch BID tape on both front and back faces. In this location,

as other places where there is an inside angle joint, fill the corner with

a small radius MICRO/FLOX fillet and wet out the bonding areas with brushed

on epoxy. Provide a uniform one inch overlap on each part.

-

Insert the 1" by 1" plywood insert at belt the line as shown in the drawing

with a 2 by 6 inch, 4 ply prelam BID front and aft of these plywood inserts.

These are "hard points" for the shoulder harness for the rear seat

passengers.

Image 126-127: Station 139.5

|

|

|

STATION 180.5

BULKHEAD

The aft tail-cone bulk head is located at station 180.5. This bulk head is

located at the leading edge of the horizontal stabilizer. The bulkhead is

cut from the pre-marked two ply prepreg panel (inside the opening of station

139.5 bulkhead).

-

This part should be cut out carefully with a fine tooth saw and located with

the front face at station 180.5 . It may need to be trimmed for proper fit

and should then be tacked into place with five minute epoxy. This bulkhead

will have to be removed temporarily during the installation of the horizontal

stabilizer, so use a minimum amount of the five minute epoxy in "tacking"

it into place.

This bulkhead will also require a hard point for mounting the rudder idler

bell crank as follows:

-

Cut a 3 inch square of the 1/4 plywood, and cut away an equal size skin (one

skin only) on the aft face of this bulkhead as shown in figure XXX.

-

Inset the plywood with MICRO slurry, and cover with 4 plies of BID large

enough for a full overlap around the patch and extending outwards to the

edge of the bulkhead as shown in the sketch (this hard point supports the

rudder idler which can have high loads applied at times by the pilot's feet).

-

Mock up the idler assembly with the two KIS-3 brackets and locate the mounting

holes on the ply insert.

-

Lightly "tack" this bulkhead in to place at the stated location - it will

be removed and permanently installed during the horizontal stabilizer

installation.