|

I have broken the door preparation into several sections to

keep

the individual pages smaller and give some logical sections.

|

|

|

|

The door skins have to be trimmed to an etched line that

is barely cut into the outer skin. I cut to just out side the

line and carefully sanded to the line. I test fit the skin before

doing the final trim. The lines proved to be surprisingly

accurate for the outside shape but not for the window. (More on

that later.) |

|

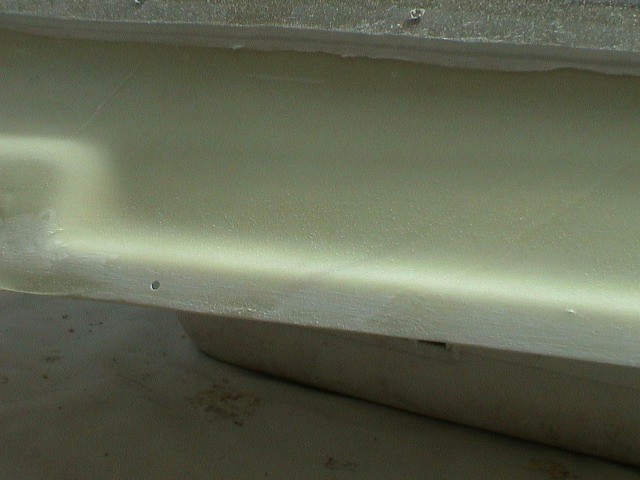

Fit of the skin was pretty good but did not quite fit as

well to the compound curvature of the door and the fuselage. I

used both tape and clecos to work the skin as best I could. |

|

This shows the close fit of the right door. The

right side door came out with an excellent fit but the left side was a

much greater problem. I only had a couple of minor voids to fill

on the right side but had to cut and rebond the middle sections (front

and rear) on the pilot side. |

|

The clecos were used to position the door skin but during

close out I applied a very tight fitting tape around the outside of the

door and the window and removed the clecos. |

|

It was very important to carefully sand the inner door

panel as well as the inside of the door skin to ensure a uniform

thickness to the glass to be bonded. This photo shows an area

where overlapping glass caused an extra thickness to the glass. |

|

The window here has been marked and sanded to prepare the

surface for bonding. |

|

An extra layer of tape has been applied along the bonding

edge. This was supposed to facilitate the clean removal of one

layer of tape prior to the adhesive curing. The adhesive I used

cured much quicker than I expected and didn't do much to help. |

|

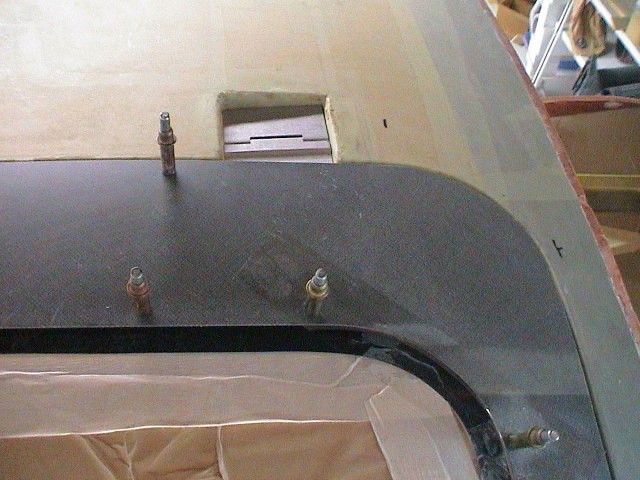

The extra layers of glass were added to both the vertical

channels to provide an area for attaching the door struts. I

located the position for the struts and installed the locking nuts in

position instead of relying on machine screws. I also added

additional glass plies across the bottom and top to add strength.

Before close I buttered a thick epoxy/flox mix to fill the area

between the inside and outside skin around the hinge area. |

| The inner door panel was placed into position

and the bonding areas buttered with adhesive. The outside skin

was also buttered and positioned using clecos. I then used tape

to hold the skin in place for curing. It worked great on one door

and not so great on the other. Not sure of why but I still

believe the tape and a minimum number of clecos was the right way to

proceed. As I mentioned above, the adhesive cured very quickly

and I had to get the clecos out (destroyed 4 in the process) and remove

the tape before I could get any photos of the close out procedure.

I was disappointed that I had tried to do too much at one time

and probably caused myself more problems than necessary. I had planned

to do each door separately but after mixing the adhesive and buttering

the bond areas on the first door, I discovered that I had prepared way

too much mixture. Instead of being smart and throwing the excess

away I continued on to the second door. That was a big mistake

and caused me to rush, the adhesive to thicken too much and I ended up

with a big problem. |